Lonnmeter Group

Lonnmeter is an professional technology company specialized in intelligent inline instruments over 15 years, having grown into a leading manufacturer of precise inline measuring instruments.

Core Positioning & Product Series

Lonnmeter focuses on the monitoring of key parameters in industrial processes and supply inline instruments likedensitometers, flowmeters, level meters (or level transmitters), viscometers and pressure transmitters to optimize industrial operation. These products enable real-time and accurate measurement of parameters such as flow rate, density, concentration, viscosity and pressure, and are widely suitable for the production process needs of multiple industries including food, chemical, cosmetics, energy, petrochemical, mining and metallury.

Choose Lonnmeter for accurate and intelligent measurement!

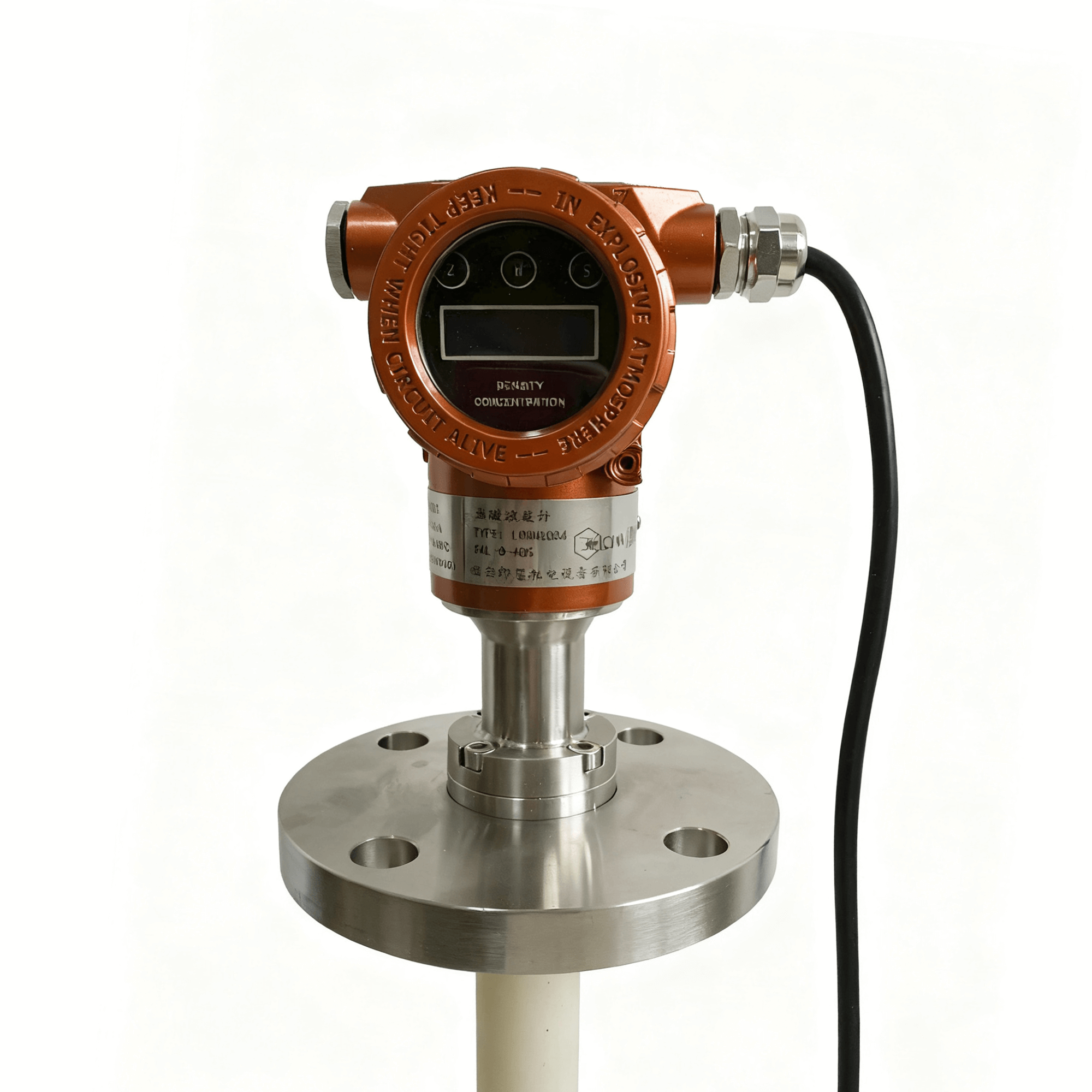

Oil Density Meter Inline

Working Principle

The tuning fork of the density meter for oil is excited by acoustic waves, leaving it to vibrate at its natural resonant frequency. Its vibration frequency is direct correlated with the density of liquids surrounding it. When the medium flows through the fork, the change of resonance frequency is caused by the change of medium quality.

Product Features

● Wide concentration measurement range 0-99% and high accuracy ±0.2%;

● Ideal for harsh conditions for temperature compensation -30 ~120 °C;

● Available anti-corrosion materials for wetted parts (Stainless steel, titanium alloy, Hastelloy alloy, PTFE, ceramic;

● Robust construction to withstand harsh conditions like high temperatures, pressures and corrosive environments;

● Fast response enables real-time density measurements for process control and quality assurance.

Interested? Contact Sales Team

Product Advantages

● Simple installation;

● Plug and play;

● Maintenance-free for no moving parts;

Applications

Some production lines or industrial plants could benefit from the inline oil density sensor:

Parameter Selection Table

| Inline Oil Density Meter | Specification Code | Tuning Fork Density Meter | |||||

| Density Measurement Range | 1 | 0~1 . 5 g/cm³ | |||||

| 2 | 0~2 g/cm³ | ||||||

| X | Others | ||||||

| Process Connection | D1 | 2" 150LB Flange | |||||

| D2 | 2" 300LB Flange | ||||||

| D3 | DN50 PN25 Flange | ||||||

| D4 | DN50 PN40 Flange | ||||||

| K1 | 2" Clamp | ||||||

| K2 | 3" Clamp | ||||||

| M1 | G3/4 Thread | ||||||

| M2 | G1 Thread | ||||||

| XX | Others | ||||||

| Material of Wetted Parts | J1 | 316 | |||||

| J2 | Titanium | ||||||

| J3 | Zirconium | ||||||

| J4 | Hastelloy-C alloy | ||||||

| JX | Others | ||||||

| Surface Treatment | A | Standard Polishing | |||||

| B | Electropolishing | ||||||

| C | PFA Coating | ||||||

| Probe Length | 0 | Standard Length | |||||

| 1 | 100 mm | ||||||

| 2 | 200 mm | ||||||

| 3 | 300 mm | ||||||

| 4 | 400 mm | ||||||

| 5 | 500 mm | ||||||

| X | Others | ||||||

| Accessories | F0 | None | |||||

| F1 | Mounting Bracket | ||||||

| F2 | Bypass Pipeline | ||||||

| F3 | Flow Cell | ||||||

| F4 | Flushing Port | ||||||

| F5 | Flange Support | ||||||

| F6 | Protective Cover | ||||||

| FX | Others | ||||||

Customization Options

I. Core Performance Customization

II. Environment and Safety Customization

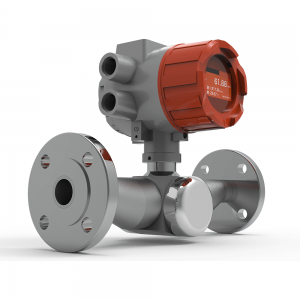

Installation

Inline Density Meter Installation Diagram

About Lonnmeter

Vision of Lonnmeter

In 3-5 years, Lonnmeter aspires to become the leader of China's new-generation wireless intelligent instruments!

In 5-10 years, Lonnmeter aspires to become China's leader in intelligent instruments and replace imported instruments with its own products!

In 10-20 years, Lonnmeter aims to make its products available to more people around the world and become a global leader in new-generation intelligent instruments!

Become the global leader of new-generation intelligent instruments.

15 + Years of Experience

Over 15 years of experience in inline instruments manufacturing.

6600 ㎡ Production Area

Over 6000 ㎡ factory and warehouse

400 + Staff

Over 400 experienced staff work for Lonnmeter like R&D, sales, marketing team, etc.

1000 -1500 Units / Month

Monthly production of inline instruments is over 1000 per month. All products undergo strict quality inspection.

Lonnmeter -- Manufacturer of Inline Instruments for Process Control

Lonnmeter (hereinafter referred to as "the Group") has grown into a competitive manufacturer of inline instruments over the past 15 years. All inline instruments undergone strict quality inspection and calibration before shipment to customers.

With joint efforts of R&D department and sales team, all inline instruments for process control escalade continuously and stand up to special and complex industrial conditions, solving numerous tricky problems and improving process efficiency while reducing costs.

Company Advantages

As a leading intelligent industrial instrument manufacturer, Lonnmeter delivers targeted, value-driven solutions for industrial process control with the following core strengths:

Complimentary Operating Condition Analysis

Our engineer team provides free professional analysis of medium properties, pressure/temperature ranges, bubble content and the like, offering data-backed recommendations to optimize parameter settings and avoid equipment selection risks.

Customized Process Control Solutions

Our portfolio is offered based on provided operating conditions and avoid all negative factors caused inaccurate measurements like flow rate, particle size and bubble content of measured media. Keep all inline instruments working in optimal status.

Flexible OEM&ODM Services

We provide tailored OEM and ODM services dedicated to inline industrial instruments. Our OEM services cover customizable packaging, operation manuals and brand logos, while ODM solutions support flexible customization of core materials, measurement parameters, product structures and functional configurations, fully meeting all your special application needs.